Bryson DeChambeau is back in the spotlight after a close finish at the PGA Championship, but the standout moment was his towering 265-yard six iron shot into the 10th at Valhalla. Well known for his power, it’s his love of tinkering with equipment and delving into the science behind his clubs that catches our attention. At the Masters this year stories broke out about Bryson using new 3D printed irons from a new manufacturer called Avoda. Avoda might be new to Byrson but 3D printed irons are not, as he’s DeChambeau has played COBRA 3D printed utility and KING TOUR since 2017.

While 3D printing is new to the mainstream, COBRA LIMIT3D irons are the first commercially available 3D printed set of irons from the brand. Cobra has created 43 different tour prototype clubs using the same technology and fourteen have made it into play over the last few years including set of Forged Tec irons specially printed for Lexi Thompson. Although costly, 3D printing offers significant time savings by eliminating the need for expensive and time-consuming tooling for forging or casting. Designs go straight from the CAD program to the printer.

Benefits of 3D Printing

In a word, performance. While COBRA LIMIT3D irons won’t add 10 more yards or guarantee flagstick-rattling precisio, they provide the forgiveness of a game-improvement iron with the compact design of a player’s iron.

Manufacturing Process of COBRA LIMIT3D Irons

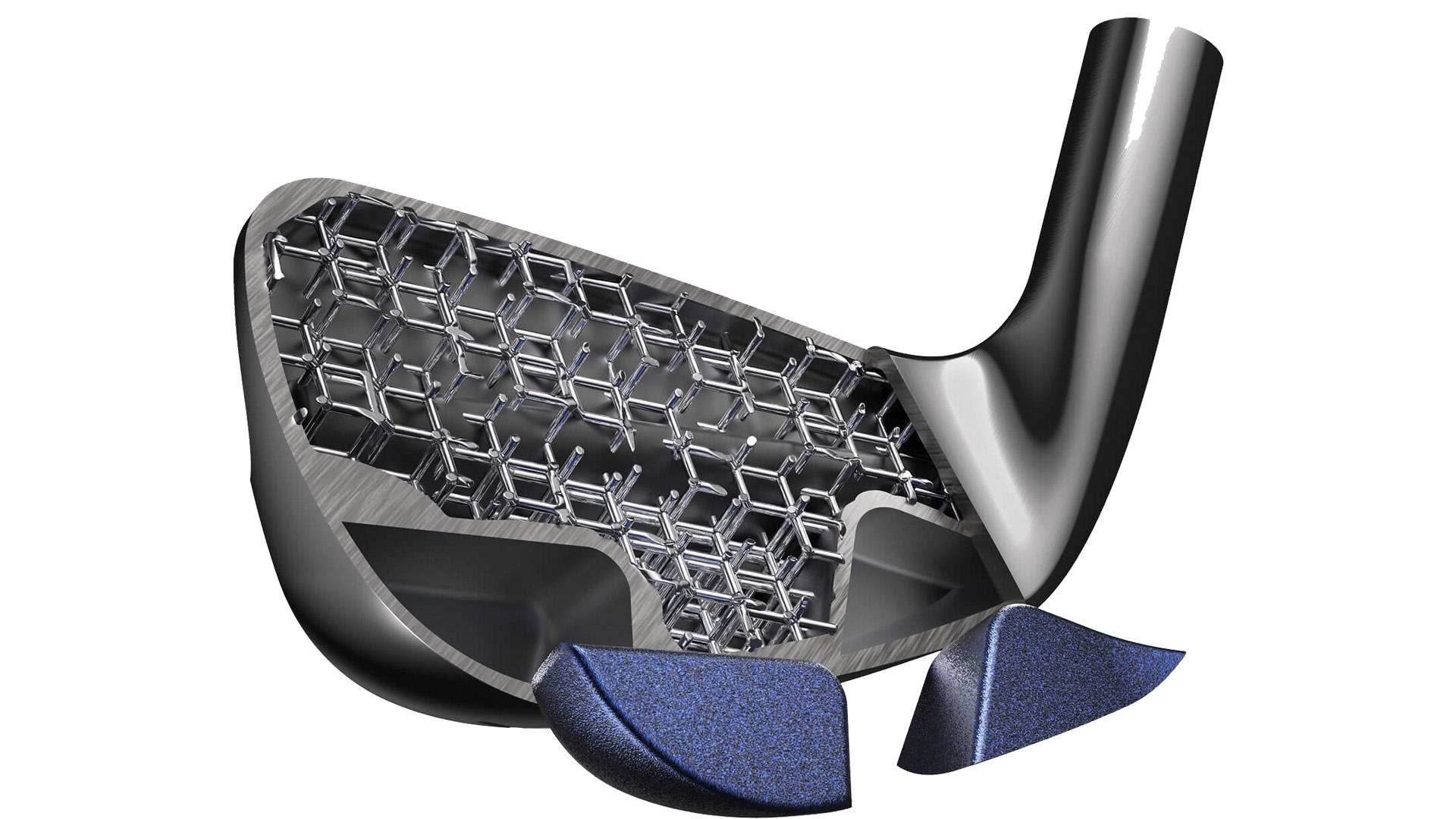

A single iron head consists of approximately 2,600 layers. The machines can print 20 heads in 24 hours. The compact yet highly forgiving club is made possible by 3D printing, which allows for more complex geometries than forging, casting, or milling. The LIMIT3D iron features a dodecahedral lattice pattern on the backside of the face, providing structural integrity while saving significant weight.

Weight Saving Benefits

With 100g of inefficient mass removed from the core of the head, Cobra replaces it with 100g of dense tungsten weighting split between the toe and heel. This positioning increases the launch and MOI, giving the look of a blade with the forgiveness of a game-improvement model. The effective tungsten placement required Cobra to adjust the lofts slightly, enhancing ball speed and distance to achieve desirable peak heights and landing angles.

Performance

In robot testing versus the KING TOUR, COBRA observed nearly 2 mph more ball speed and an additional five yards of distance with a 7-iron. The LIMIT3D is a degree stronger, but its shaft is slightly shorter. Expanding testing to include off-center hits, the LIMIT3D is longer and offers tighter dispersion, providing game-improvement performance from a Tour-sized footprint.

Conclusion

More speed, higher launch, and more forgiveness in an eye-pleasing package get our vote. The downside is only two sets are coming into the UAE via eGolf Megastore, so act quickly. With only 500 pieces available worldwide, these could become the most sought-after clubs on the market. Once a more efficient 3D production process is found, more variants are expected to hit the market.